03 February 2023

The Furniture Design Process: How Inspiring Spaces Turn into Reality

DISCOVER OUR TRADE PRICELIST: YOUR GO-TO RESOURCE FOR EXCLUSIVE FURNITURE OFFERS

Product added to Wishlist

Product removed from wishlist

Product added to cart

Product added to cart

CartAdded to the comparator

Removed from comparator

To start the search enter at least 3 characters of a description, brand or reference number

03 February 2023

Search here...

Most Popular Articles

Subscribe to the Newsletter

Receive offers and news tailored to you

| Use to view more |

|---|

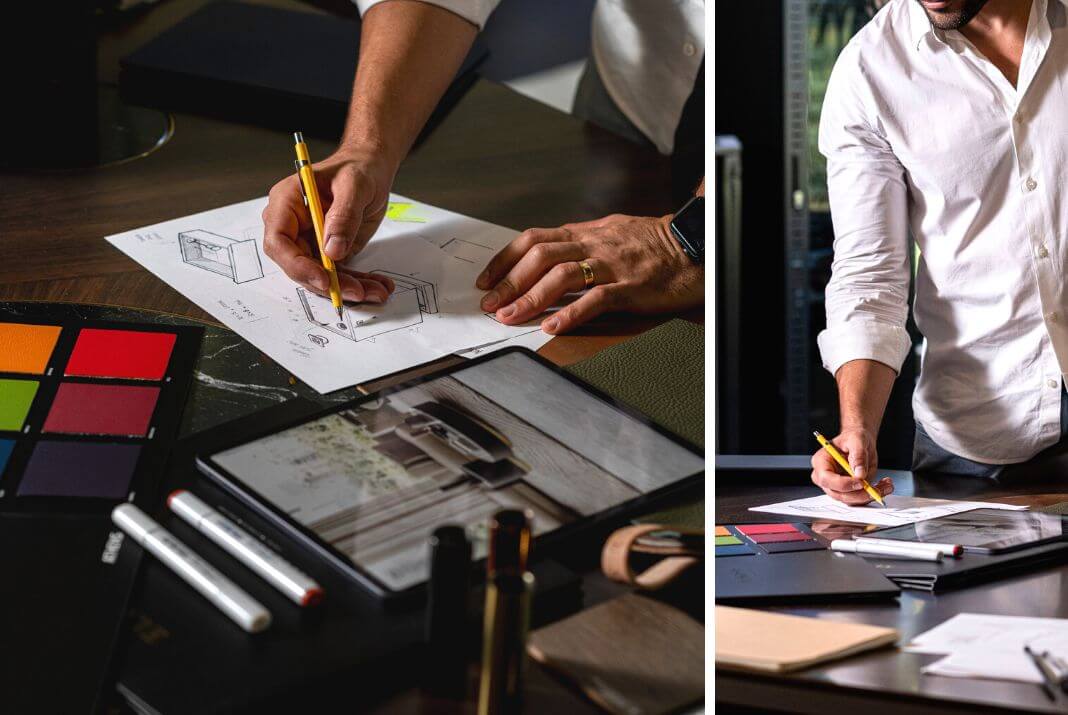

From Design to Creation: The Jeane Dining TableFurniture plays a crucial role in defining the functionality and aesthetic of homes and workplaces. It can range from simple and functional to intricate and decorative. The process of making it always starts with the design of the piece: With a pencil and a notebook. |

| Use to view more |

|---|

The design process for the Jeane Dining Table began with a concept, as well as a vision of what we wanted the piece to represent. The idea was influenced by various factors such as the intended use of this dining table, its size, the overall style, and the current trends in design. |

| Use to view more |

|---|

Choosing the Right Materials |

| Use to view more |

|---|

Once the design was finalized, the next step was to choose the right materials for the Jeane dining table. This included the type of wood, metal, glass, and marble that were used. The choice of materials can have a significant impact on the overall look, durability, and cost of the furniture. So, before everything else, we wanted to be sure about what we chose |

| Use to view more |

|---|

Manufacturing Process |

| Use to view more |

|---|

The actual manufacturing of the Jeane dining table involved a series of processes that turn raw materials into a finished piece. This included cutting and shaping the wood, welding, sanding metal and working with marble stones. |

| Use to view more |

|---|

Final Assembly and Finishing |

| Use to view more |

|---|

Once the individual components of the Jeane dining table were made, the next step was to assemble and finish the piece. This included attaching legs, and hardware, and sanding and staining the surface to create a smooth finish. In some cases, the furniture may also be treated with a protective coat to enhance its durability and longevity. |

| Use to view more |

|---|

| Use to view more |

|---|

the final result: |

| Use to view more |

|---|

From Design to Creation: The Dale ChairFurniture plays a crucial role in defining the functionality and aesthetic of homes and workplaces. It can range from simple and functional to intricate and decorative. The process of making it always starts with the design of the piece: With a pencil and a notebook. |

| Use to view more |

|---|

The design process for the Jeane Dining Table began with a concept, as well as a vision of what we wanted the piece to represent. The idea was influenced by various factors such as the intended use of this dining table, its size, the overall style, and the current trends in design. |

| Use to view more |

|---|

Choosing the Right Materials |

| Use to view more |

|---|

Once the design was finalized, the next step was to choose the right materials for the Dale Chair. This included the type of wood, metal and upholstery that was going to be used. The choice of materials can have a significant impact on the overall look, durability, and cost of the furniture. So, before everything else, we wanted to be sure about what we chose |

| Use to view more |

|---|

Manufacturing Process |

| Use to view more |

|---|

The actual manufacturing of the dale chair involved a series of processes that turn raw materials into a finished piece. This included cutting and shaping the wood, welding and sanding metal. |

| Use to view more |

|---|

Final Assembly and Finishing |

| Use to view more |

|---|

Once the individual components of the Dale Chair were made, the next step was to assemble and finish the piece. This included attaching legs, and hardware and finish the upholstery. In some cases, the furniture may also be treated with a protective coat to enhance its durability and longevity. |

| Use to view more |

|---|

The Final Result: |

| Use to view more |

|---|

| Use to view more |

|---|

From Design to Creation: The Ambrose Armchair |

| Use to view more |

|---|

The design process for the Ambrose Armchair began with a concept, as well as a vision of what we wanted the piece to represent. The idea was influenced by various factors such as the intended use of this armchair, its size, the overall style, and the current trends in design. |

| Use to view more |

|---|

Choosing the Right Materials |

| Use to view more |

|---|

Once the design was finalized, the next step was to choose the right materials for the Ambrose Armchair. This included the type of wood, metal and upholstery that was going to be used. The choice of materials can have a significant impact on the overall look, durability, and cost of the furniture. So, before everything else, we wanted to be sure about what we chose |

| Use to view more |

|---|

Manufacturing Process |

| Use to view more |

|---|

The actual manufacturing of the Ambrose Armchair involved a series of processes that turn raw materials into a finished piece. This included cutting and shaping the wood, welding and sanding metal. |

| Use to view more |

|---|

Final Assembly and Finishing |

| Use to view more |

|---|

Once the individual components of the Ambrose Armchair were made, the next step was to assemble and finish the piece. This included attaching legs, and hardware and finish the upholstery. In some cases, the furniture may also be treated with a protective coat to enhance its durability and longevity. |

| Use to view more |

|---|

The final Result: |

| Use to view more |

|---|

| Use to view more |

|---|

From Design to Creation: The Wellington SofaFurniture plays a crucial role in defining the functionality and aesthetic of homes and workplaces. It can range from simple and functional to intricate and decorative. The process of making it always starts with the design of the piece: With a pencil and a notebook. |

| Use to view more |

|---|

The design process for the Wellington Sofa began with a concept, as well as a vision of what we wanted the piece to represent. The idea was influenced by various factors such as the intended use of this sofa, its size, the overall style, and the current trends in design. |

| Use to view more |

|---|

Choosing the Right Materials |

| Use to view more |

|---|

Once the design was finalized, the next step was to choose the right materials for the Wellington Sofa. This included the type of wood, metal and upholstery that was going to be used. The choice of materials can have a significant impact on the overall look, durability, and cost of the furniture. So, before everything else, we wanted to be sure about what we chose |

| Use to view more |

|---|

Manufacturing Process |

| Use to view more |

|---|

The actual manufacturing of the Wellington Sofa involved a series of processes that turn raw materials into a finished piece. This included cutting and shaping the wood, welding and sanding metal. |

| Use to view more |

|---|

Final Assembly and Finishing |

| Use to view more |

|---|

Once the individual components of the Wellington Sofa were made, the next step was to assemble and finish the piece. This included attaching legs, and hardware, and sanding and staining the surface to create a smooth finish. In some cases, the furniture may also be treated with a protective coat to enhance its durability and longevity. |

| Use to view more |

|---|

The final result: |